Axial Fans

Comprehensive range of bespoke and standardized axial fans critical to demanding processes across multiple industries including mining, power, tunnel ventilation, metals processing, aeration, drying and smoke extraction.

Leading the world in raising energy efficiency, improving reliability and reducing lifetime costs for our customers. Design and manufacture of bespoke and standardized fans and comprehensive aftermarket support for current Howden and Alphair products, owned legacy brands including Buffalo Forge, Turbowerke Meisen and Nordisk plus 3rd party brands.

Exploded view and airflow through the Variax variable pitch axial fan that is widely used across the mining, power and metal processing sectors and in wind tunnels.

The Alphair fans are heavy-duty axial fans designed specifically for main mine ventilation. These robust adjustable-pitch fans can be installed vertically or horizontally to supply critical air or remove stale air and gases. A comprehensive flow of up to 1 million CFM (1.7m m3/h) can be achieved while meeting the high standards in efficient operation and low maintenance through reliable service.

Download our brochure for more information.

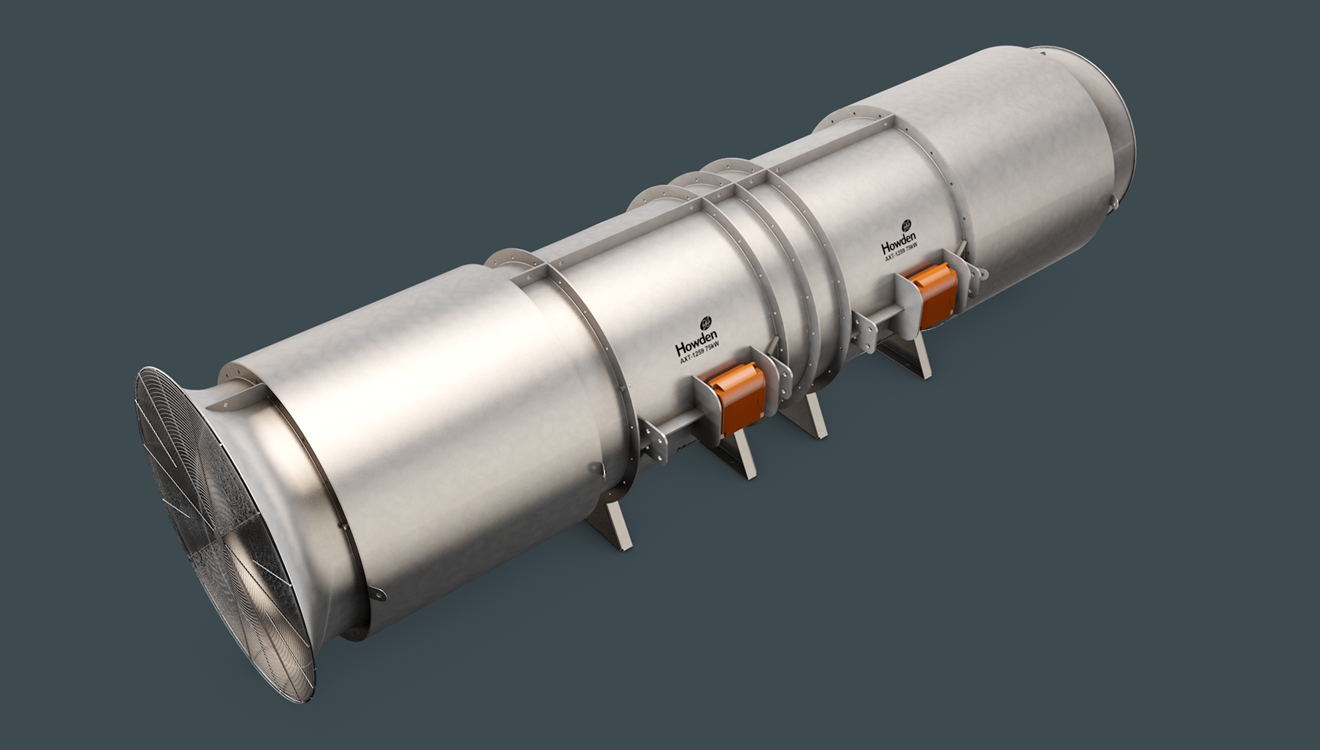

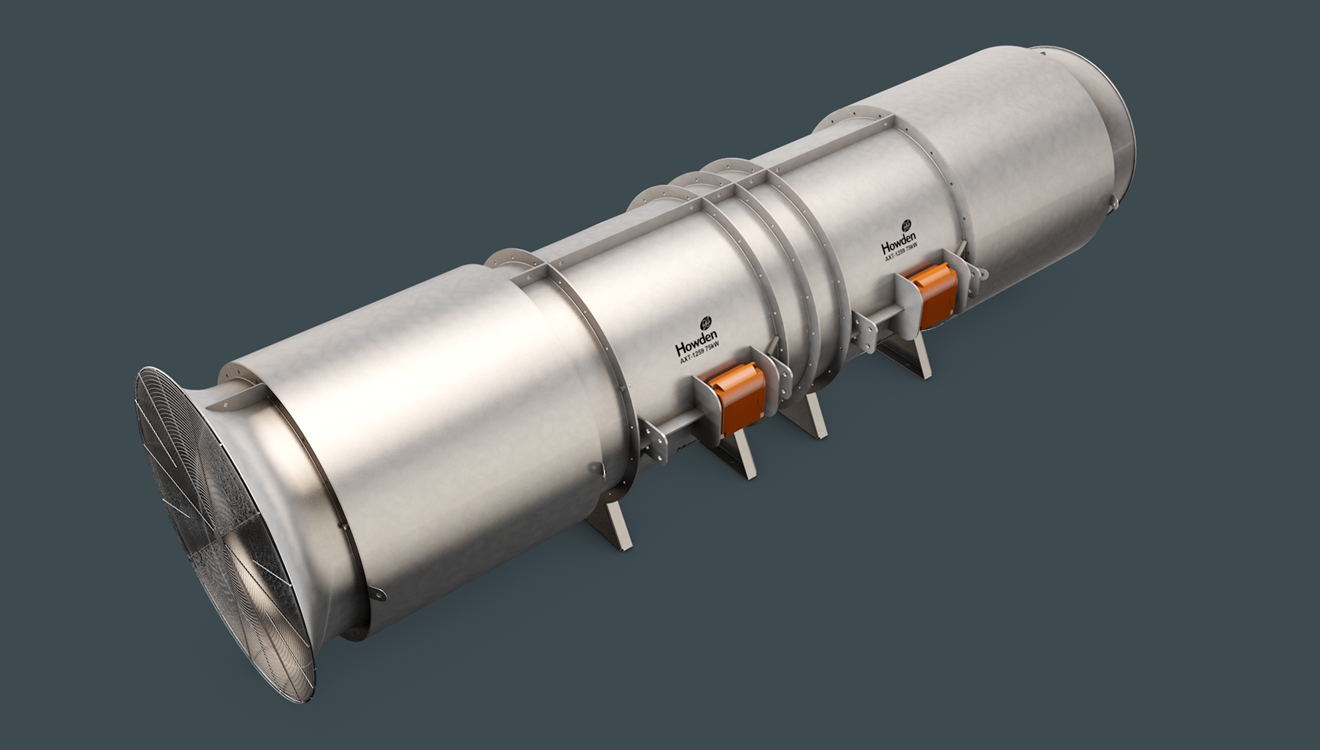

Howden’s Jetstream AX fans are specifically designed to give the highest fan output at low power consumption, providing high efficiencies of up to 85% across a broad operating range. They are ideally suited to provide auxiliary or secondary ventilation within underground mines fans although can also be deployed for main air supply.

Their modular design gives commonality of parts and flexibility on the arrangement, components, number of stages, thereby allowing customization if needed.

Download our product leaflet for more information.

Variable pitch axial fans combining the highest efficiency levels available today with an exceptionally flexible, customer focused design. The Variax and PF fans are proven across a wide range of applications within mining, power, metals and wind tunnels.

The fans are fully custom-made design to order specification and offer a wide range of configurations and performance envelopes to match each application.

The VA series of industrial axial fans are designed for continuous operation and are highly dependable. They are used within applications such as ventilation, aeration and drying, extraction, cooling and air conditioning. The range is highly flexible to specific customer requirements with Howden engineers able to provide design adjustments and offer different configurations. ATEX-classification is available on request.

The UMAF range is ideal for applications requiring air or extraction of air/gases in flows of up to 400 m3/s. These fans are extensively used with tunnel ventilation/smoke extraction, Industrial process for combustion air, and in higher-pressure Direct Air (carbon) Capture systems

Fans can operate uni-directional or fully reversible. Flow control is enabled by blade adjustment either at standstill or during operation depending on model selected and also achieved using a Variable Speed Drive (VSD)

In the case of tunnel ventilation, they are tested to operate at 200ºC/1h or up to 400ºC/2h.

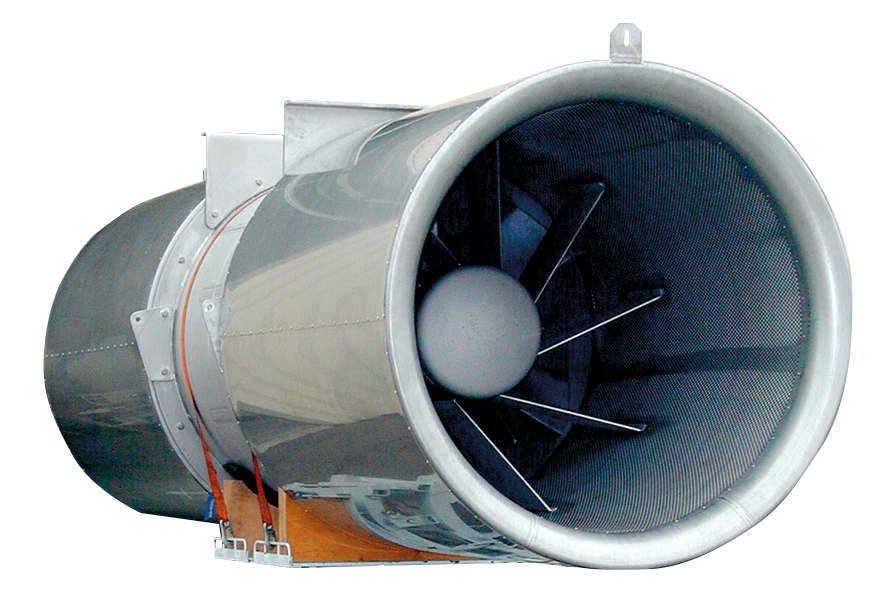

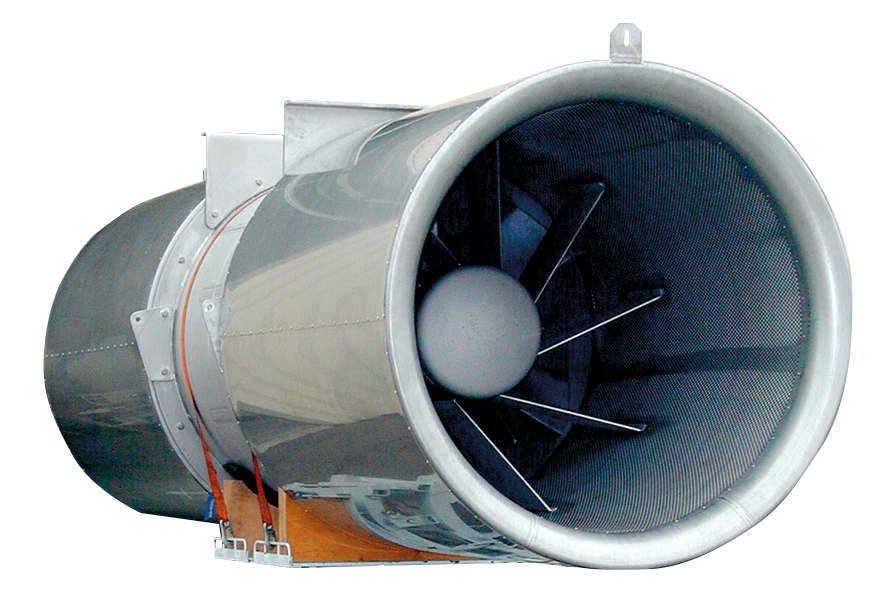

Jet fans are typically used in tunnel ventilation systems using the longitudinal technique with single or bi-directional traffic. The AP/Q range can operate with flows of up to 50 m3/s with thrust of up to 3360N

Fans can operate uni-directional or fully reversible (uni-directional may also operate in reverse with a lower thrust). Flow control is achieved using a Variable Speed Drive (VSD).

Wide range of standard sizes, all incorporating rotors that are dynamically balanced to eliminate vibration and noise. Fans can be fitted with silencers for outstandingly quiet operation and are tested to operate at 200ºC/1h or up to 400ºC/2h

Our service capability encompasses all axial fans from own brands to those of other manufacturers.

For own fan brands we offer a complete range of aftermarket solutions from OEM spare parts, analysis and troubleshooting and general maintenance, to fully engineered upgrades and retrofits for operational performance and life extension.

Our brands include those currently available as new equipment such as Howden and Alphair, but also those acquired over the course of our 160 years of history such as:

The Alphair fans are heavy-duty axial fans designed specifically for main mine ventilation. These robust adjustable-pitch fans can be installed vertically or horizontally to supply critical air or remove stale air and gases. A comprehensive flow of up to 1 million CFM (1.7m m3/h) can be achieved while meeting the high standards in efficient operation and low maintenance through reliable service.

Download our brochure for more information.

Howden’s Jetstream AX fans are specifically designed to give the highest fan output at low power consumption, providing high efficiencies of up to 85% across a broad operating range. They are ideally suited to provide auxiliary or secondary ventilation within underground mines fans although can also be deployed for main air supply.

Their modular design gives commonality of parts and flexibility on the arrangement, components, number of stages, thereby allowing customization if needed.

Download our product leaflet for more information.

Variable pitch axial fans combining the highest efficiency levels available today with an exceptionally flexible, customer focused design. The Variax and PF fans are proven across a wide range of applications within mining, power, metals and wind tunnels.

The fans are fully custom-made design to order specification and offer a wide range of configurations and performance envelopes to match each application.

The VA series of industrial axial fans are designed for continuous operation and are highly dependable. They are used within applications such as ventilation, aeration and drying, extraction, cooling and air conditioning. The range is highly flexible to specific customer requirements with Howden engineers able to provide design adjustments and offer different configurations. ATEX-classification is available on request.

The UMAF range is ideal for applications requiring air or extraction of air/gases in flows of up to 400 m3/s. These fans are extensively used with tunnel ventilation/smoke extraction, Industrial process for combustion air, and in higher-pressure Direct Air (carbon) Capture systems

Fans can operate uni-directional or fully reversible. Flow control is enabled by blade adjustment either at standstill or during operation depending on model selected and also achieved using a Variable Speed Drive (VSD)

In the case of tunnel ventilation, they are tested to operate at 200ºC/1h or up to 400ºC/2h.

Jet fans are typically used in tunnel ventilation systems using the longitudinal technique with single or bi-directional traffic. The AP/Q range can operate with flows of up to 50 m3/s with thrust of up to 3360N

Fans can operate uni-directional or fully reversible (uni-directional may also operate in reverse with a lower thrust). Flow control is achieved using a Variable Speed Drive (VSD).

Wide range of standard sizes, all incorporating rotors that are dynamically balanced to eliminate vibration and noise. Fans can be fitted with silencers for outstandingly quiet operation and are tested to operate at 200ºC/1h or up to 400ºC/2h

Our service capability encompasses all axial fans from own brands to those of other manufacturers.

For own fan brands we offer a complete range of aftermarket solutions from OEM spare parts, analysis and troubleshooting and general maintenance, to fully engineered upgrades and retrofits for operational performance and life extension.

Our brands include those currently available as new equipment such as Howden and Alphair, but also those acquired over the course of our 160 years of history such as:

Access and download literature, specifications, case studies and more.

Head Office +44 141 885 7500