CPI

Proven Solutions for the Global Compression Industry. Throughout the world, our customers count on us for service and solutions that keep their compressors, lubrication systems, and business running.

Get a Quote Now!CPI lubrication parts are now available with reduced lead times. Whether you need a quick quote or immediate shipment, we have got you covered. Discover the convenience of our ready-to-ship solutions.

With roots dating back to 1897, originally known as France Compressor Products, Compressor Products International (CPI) has grown tremendously, developing and acquiring new technologies and services to better meet the global needs of today’s reciprocating compressor operators.

Throughout the world, our customers count on us for service and solutions that keep their compressors, lubrication systems, and business running. With our thorough knowledge of compressor operation and extensive field experience gained from years of collaboration with compressor manufacturers and users, we are proud to help drive growth in the markets we serve.

Our health and safety goal is clear — to have the world's safest employees. All employees sign a pledge to help achieve this objective. We believe every accident can be prevented, and our safety framework is designed to eliminate all incidents associated with CPI activities, products and services.

Training and education programs and ongoing process improvement help ensure full engagement of our workforce in our safety goals. Safety must be present in every aspect of our product life cycle: from the suppliers with whom we partner, to the employees who build and distribute our products.

CPI is committed to keeping your compressors operating safely, reliably and profitably. View our informational videos to learn more.

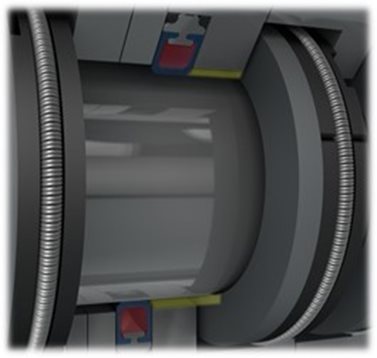

Reciprocating compressors and particularly the main pressure packing cases are known to be large contributors to the overall gas emissions from plants. For this reason, CPI have invested much time and resources to develop unique solutions to help solve this industry wide problem.

CPI’s EMISSIONGUARD™ TR² packing ring is the only ring design that multiplies the benefits of a tangent to rod ring and a step tangent ring by combining the two rings into one, providing a more efficient seal whilst reducing the frictional load onto the piston rod.

Proven in the field to consistently reduce packing case vent leakage by 50% and more.

The CPI EMISSIONGUARD™ ES³ expandable static seal is the first seal designed for optimum sealing when your compressor is not running and remains pressurized.

CPI can supply a full control system which can interlock with the compressor controls to activate and deactivate the ES³ static seal only when the compressor is stopped.

Control and monitor the pressure of the buffer gas into the packing case assemblies.

Monitoring vent line pressure and flow enabling automatic regulation of the inert buffer gas pressure.

CPI’s purge panels ensure a positive buffer gas pressure in line with API618 to prevent process gas leakage into the distance piece.

Together with our EMISSIONGUARD™ family of products we also design, manufacture and supply all conventional main, intermediate and wiper packing cases and rings. CPI manufactures all of our polymer materials in-house using proprietary blends and methods. This ensures that we have total control of the quality and performance of our products. Our engineers select the best materials for each application to optimize the performance and reliability of our products in service.

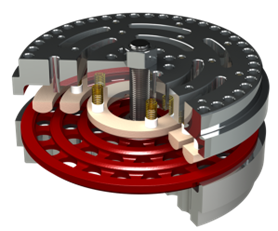

CPI have built a reputation as a valve problem solver with our signature Hi-Flo™ Profiled Ring Valve range. Each valve is specifically designed for the application to provide reliability and durability.

We have also taken our profiled ring valve a step further by developing our RS (Replaceable Seat) valve, this is based on our radius ring valve, bringing the same performance, but with the added advantage of not requiring any machining of valve seat, with a simple clean and replacement of all internal consumables including the non-metallic replaceable seat plate.

To access CPI's comprehensive collection of brochures for all valve products, visit the Technical Library below, select the brochures section and scroll down alphabetically to all literature prefixed Valves.

The oil and lubrication system plays a very significant role in the performance of a reciprocating compressor. Too much, too little or inconsistent delivery can reduce performance, lead to premature wear and potentially result in catastrophic failure.

CPI provides industry leading lubrication systems, products and services, partnering with our customers to develop individual solutions to their unique lubrication needs.

From individual components to complete, turnkey systems like our SAFEGUARD™ 1000 or SAFEGUARD™ 5000 lube consoles, we can provide the resources and expertise to ensure your compressor operates at peak performance and longevity.

To access CPI's comprehensive collection of brochures for all lubrication products, visit the Technical Library below, select the brochures section and scroll down alphabetically to all literature prefixed Lubrication.

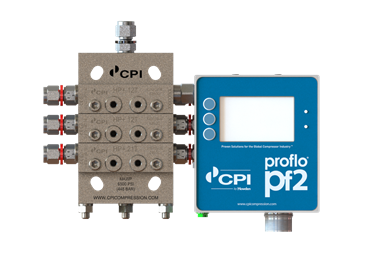

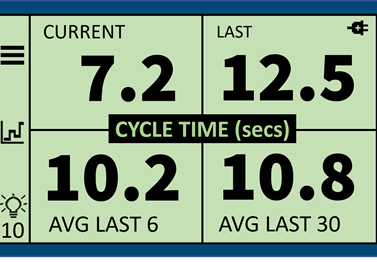

Proflo PF2 is a programmable shutdown device used to monitor the lubricant flow of divider valve metering systems. It is a learning device that monitors and calibrates to the installed magnet assembly

Proflo PF2 lets users set up alarms and signals for shutdowns or warnings. It has tools to test and check settings easily, making installation and troubleshooting simpler.

![]()

Proflo® PF2 Connect is a mobile app that provides PF2 device users the ability to connect with all their PF2 devices in order to download & maintain device data, update device firmware, and manage their device IDs.

CPI provides exceptional reconditioning services for restoring parts to their original specifications and performance.

Whenever a part has the potential to be made “good as new,” CPI has the expertise to make it happen. Using various NDT methods, CPI experts will carefully evaluate the condition of components identifying the root causes of problems to arrive at an optimal solution.

CPI field service engineers are highly experienced technical experts capable of fully servicing many compressor makes and models, either individually, as a maintenance team working on-site with an operator’s own personnel or supervising third party service personnel.

Our reputation on customer sites is highly regarded and our expertise is utilized on the most critical of installations. Through our component and full compressor knowledge, we bring the optimum level of total compressor support.

CPI has a comprehensive library of supporting technical information including brochures, spec sheets, operating manuals, declarations of conformity (certification), case studies and technical bulletins. Access everything from the technical library.

United States, Stafford, TX +1 (281) 207-4600

CPI BATON ROUGE

11997 Airline Hwy

Baton Rouge, LA

70817

Phone: (225) 752-4272

CPI CALIFORNIA

3835 E. Vernon St.

Long Beach, CA

90815

Phone: (310) 223-1101

CPI STAFFORD (HOUSTON)

4410 Greenbriar Drive

Stafford, TX 77477

Phone: (281) 207-4600

CPI PHILADELPHIA

107 William Leigh Drive

Tullytown, PA 19007

Phone: (215) 946-0845

CPI BRANTFORD

124 Shaver Street

Brantford, Ontario, Canada

N3T 5M1

Phone: (519) 753-8671

CPI EDMONTON

6308 Davies Rd NW

Edmonton, Alberta, Canada

T6E 4M9

Phone: (780) 468-5145

CPI CHINA

28-3 Rongle East Roads

Shanghai, China 201612

Phone: +86 (0) 21 67871990

HOWDEN & CPI SOUTH KOREA

12-1, Sanan-Ro, Nam-gu

Ulsan, Republic of Korea, 44781

Seoul Office: +82 (0)2 6022 2393

Ulsan Workshop +82 (0)52 266 1011

CPI FRANCE

95 Rue de Neuf-Mesnil,

Bâtiment A8

Feignies, France 59750

Phone: +33 (0) 327 63 16 64

CPI SPAIN

Calle La Granja Nº 41

Alcobendas, Madrid, Spain

28108

Phone: +34 91 651 93 55

CPI UK

Unit 5 Smitham Bridge Road

Hungerford, RG17 0QP

Phone: +44 (0)1488 684 585

CPI NETHERLANDS

Harregatplein 17

Zuidland, Netherlands 3214

VP Zuidland

Phone: +31 (0) 1816 63149