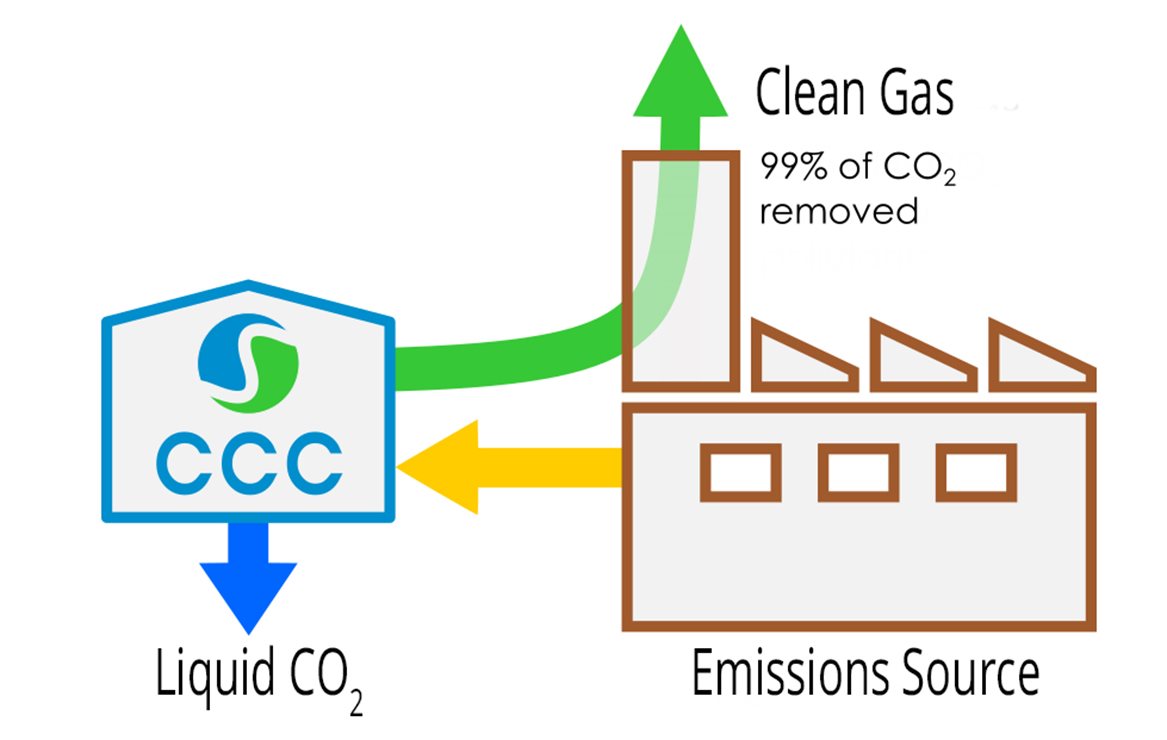

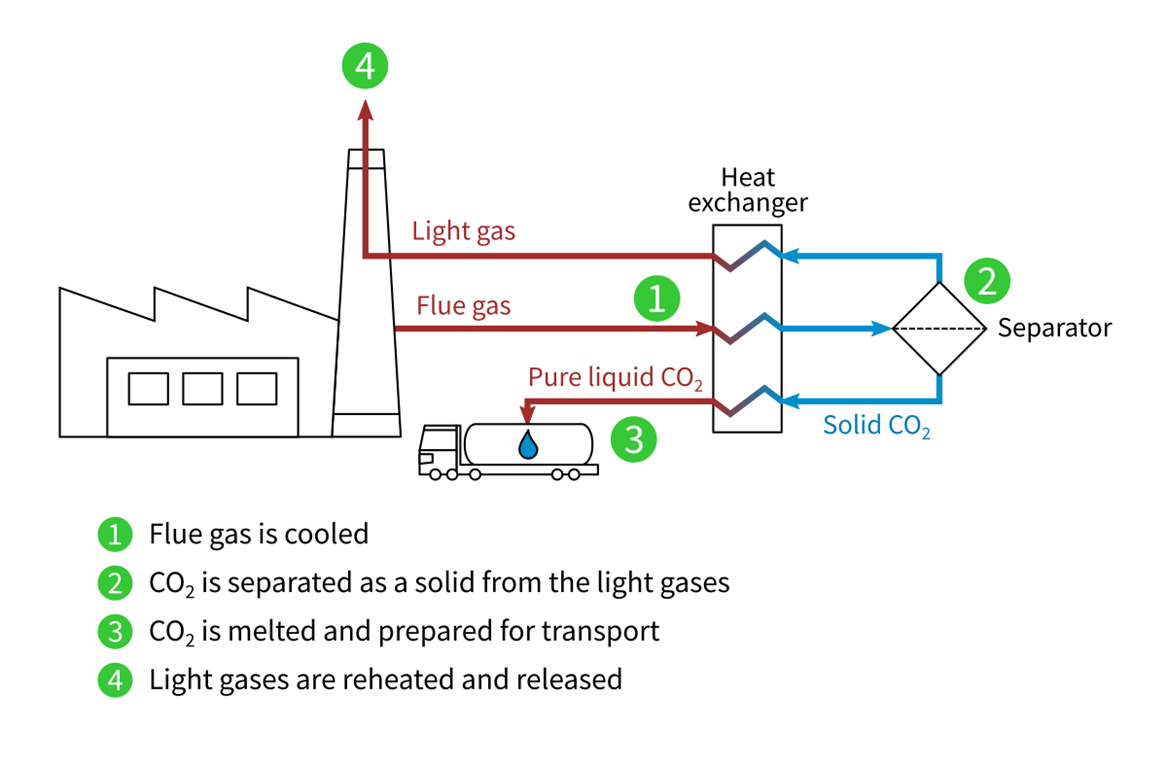

CCUS - Cryogenic Carbon Capture™

Cryogenic Carbon Capture™ (CCC) is a post-combustion technology that reduces carbon emissions from fossil energy power stations, cement, pulp and paper, iron and steel facilities as well as certain chemical production plants.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team