Cement Production

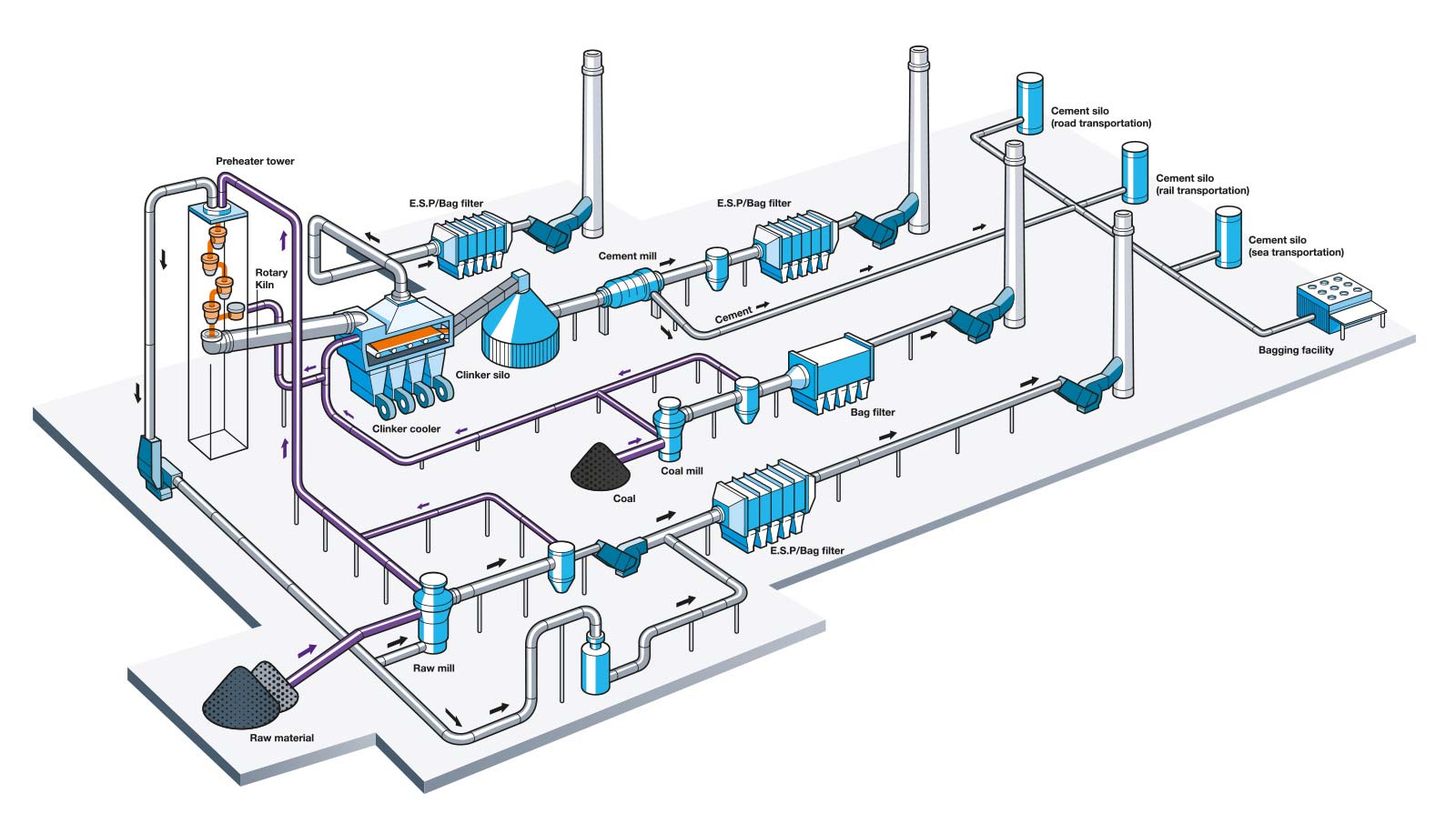

Howden fans and blowers are used throughout the cement production process from mineral extraction to storage and transportation. Cryogenic Carbon Capture virtually eliminates emissions from the manufacturing process.

At each stage of the process Howden’s expertise in air and gas handling equipment ensures reliable and efficient performance enabling our customers production to continue. All our products are supporting by a global engineering service network capable to optimising existing fans, blowers, ESPs and bag houses as well as providing the latest technology for new build and replacement service.

Howden has a long history of fans supporting the cement manufacturing process. Our centrifugal fans are engineered to meet the precise demands of each application. Our ID fans are found in:

Our centrifugal fans are used to draw exhaust air from the Kiln preheater as well as the clinker cooler. Our fans can also be used in the cooling process to circulate fresh air to the clinker to cool down the material.

Through our Rothemühle business we have the knowledge and expertise to provide efficiency and life extension improvements to existing Electrostatic precipitators and bag filtering systems.

Howden has a long history of fans supporting the cement manufacturing process. Our centrifugal fans are engineered to meet the precise demands of each application. Our ID fans are found in:

Our centrifugal fans are used to draw exhaust air from the Kiln preheater as well as the clinker cooler. Our fans can also be used in the cooling process to circulate fresh air to the clinker to cool down the material.

Through our Rothemühle business we have the knowledge and expertise to provide efficiency and life extension improvements to existing Electrostatic precipitators and bag filtering systems.

Post combustion technology that virtually eliminates carbon dioxide emissions from cement manufacture. Captured carbon dioxide is purified and liquefied and available for storage and transportation. Liquid carbon dioxide is a valuable commodity that can be used in the cement making process, as well as a host of other uses, such as food processing and preservation, beverage carbonation, brewing and water treatment.

Access and download literature, specifications, case studies and more.

Head Office +44 141 885 7500