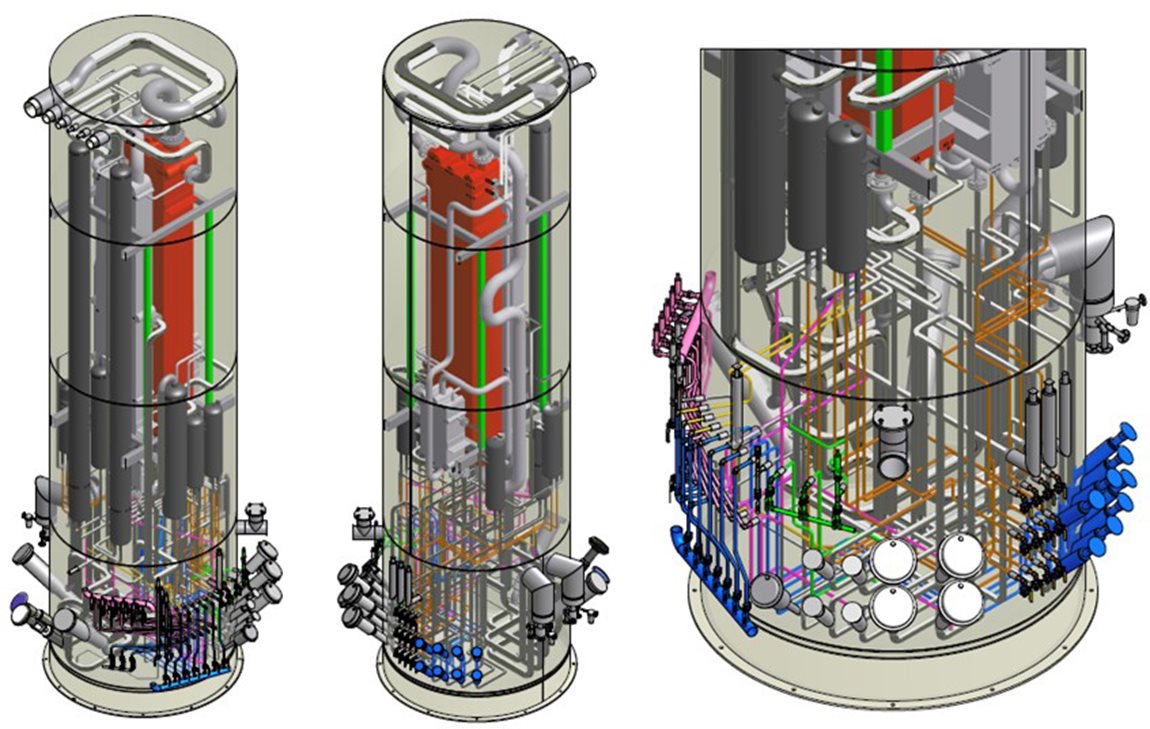

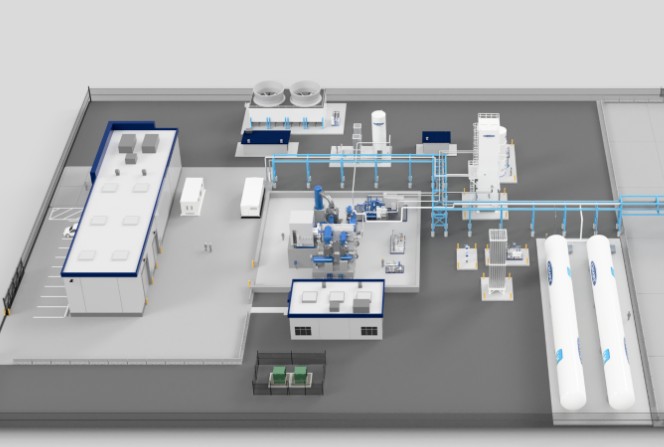

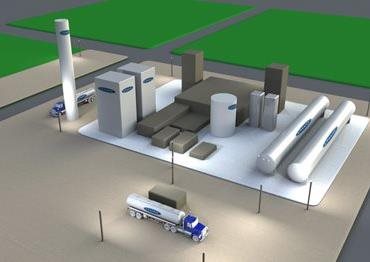

Hydrogen Liquefiers

Complete in-house engineered and manufactured hydrogen liquefaction plant equipment with capacities ranging from 5 to over 150 tons per day. Standard sizes at 5, 10, 15, 30 and 150 tons per day, with history of multiple built and operating plants.

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team