Non-Ferrous Metals

Non-ferrous metals, such as Copper, Aluminium, Zinc and Nickel, are a key component in many industrial and technology based manufactured products currently see rising demand. The production processes are energy intensive and so production equipment must contribute to goals to lessen environmental impact and increase efficiencies.

Howden products are there at the start, used within underground mines for ventilation (see mining). When it comes to the processing stages, multiple methods are used, which involve Howden's air and gas handling technology.

Aluminium

Primary aluminium manufacture is accomplished involves refining bauxite ore to obtain aluminium oxide (Bayer process) and smelting the aluminium oxide to release pure aluminium (Hall-Heroult process).

Our MVR compression expertise is supporting efficiency within Alumina refining. Our fans are deployed within the calcination process for primary air and flue gas exhaust as well as in smelting as part of the fluidization system.

Copper

Howden equipment is found mainly in the pyrometallurgical process based on sulfide ores.

Our centrifugal blowers/compressors supply air or oxygen to assist combustion within the smelter. Sulphuric acid is a by-product of the smelting process. After the waste gas is cleaned in the Sulphuric Acid Plant (SAP), the SO2 is dried in a Drying Tower, which is then typically followed by the SO2 main blower. Centrifugal compressors/blowers are the typical design choice and can be supplied with electric motor or steam turbine driven.

During the conversion process, our blowers provide blast air to be blown through the tuyeres, into the molten bath. Sometime these are steam turbine driven, which we can supply separately or as an integrated unit.

Within the hydrometallurgical process, our centrifugal fans can be found providing aeration within heap leaching pads.

Nickel/Zinc/Lead

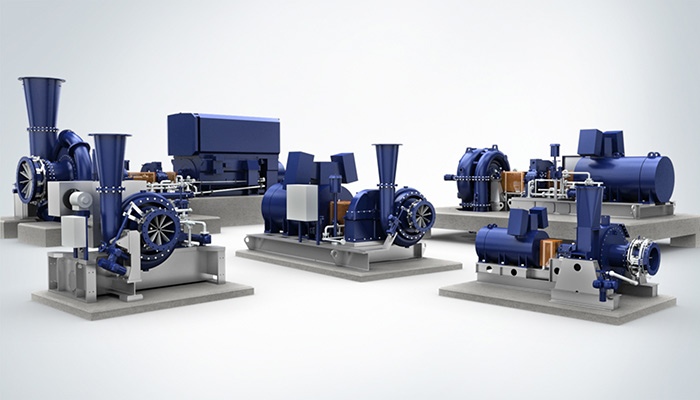

Across the various processes, Howden compressors, blowers, and fans play a role providing combustion air for smelting, air for calcination and sintering, and for flotation. Where Sulphuric Acid production is present, our blowers are relied upon to handle SO2.

Applicable Products:

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team