Marine Systems

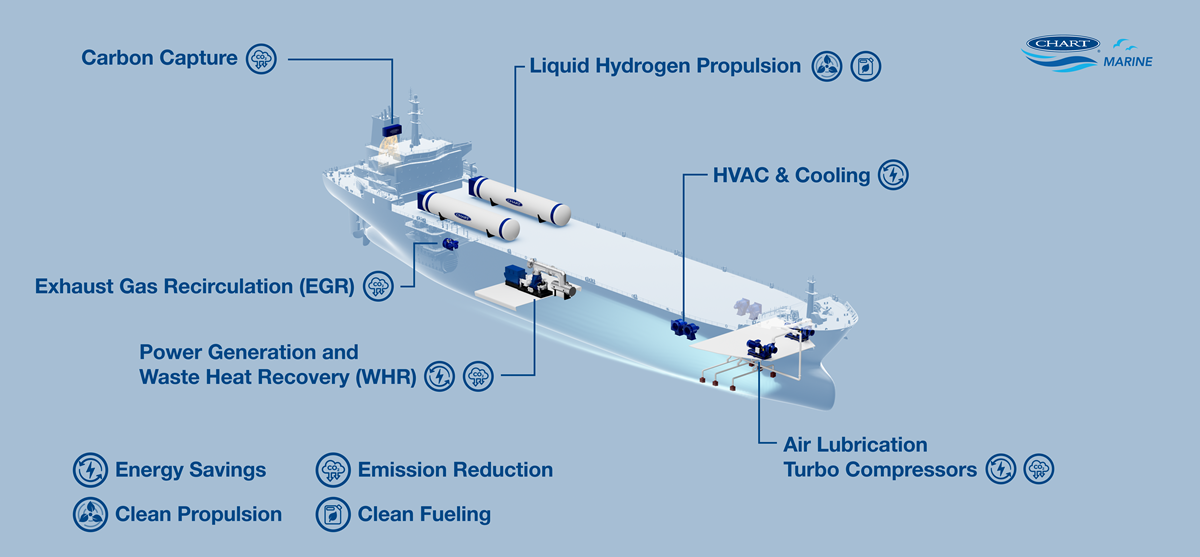

Combining compression and cryogenic expertise to create solutions for decarbonizing the marine industry through clean propulsion, onboard energy saving and emission reduction.

Clean propulsion through LNG and hydrogen Fuel Gas Supply Systems (FGSS) and the shore to ship bunkering infrastructure for refueling. Exhaust gas recirculation and capture systems directly reduce emissions, while air lubrication, waste heat recovery solutions and steam turbines reduce energy consumption.

A portfolio of products developed and/or adapted to reduce emissions, decarbonize and improve efficiency in the marine sector.

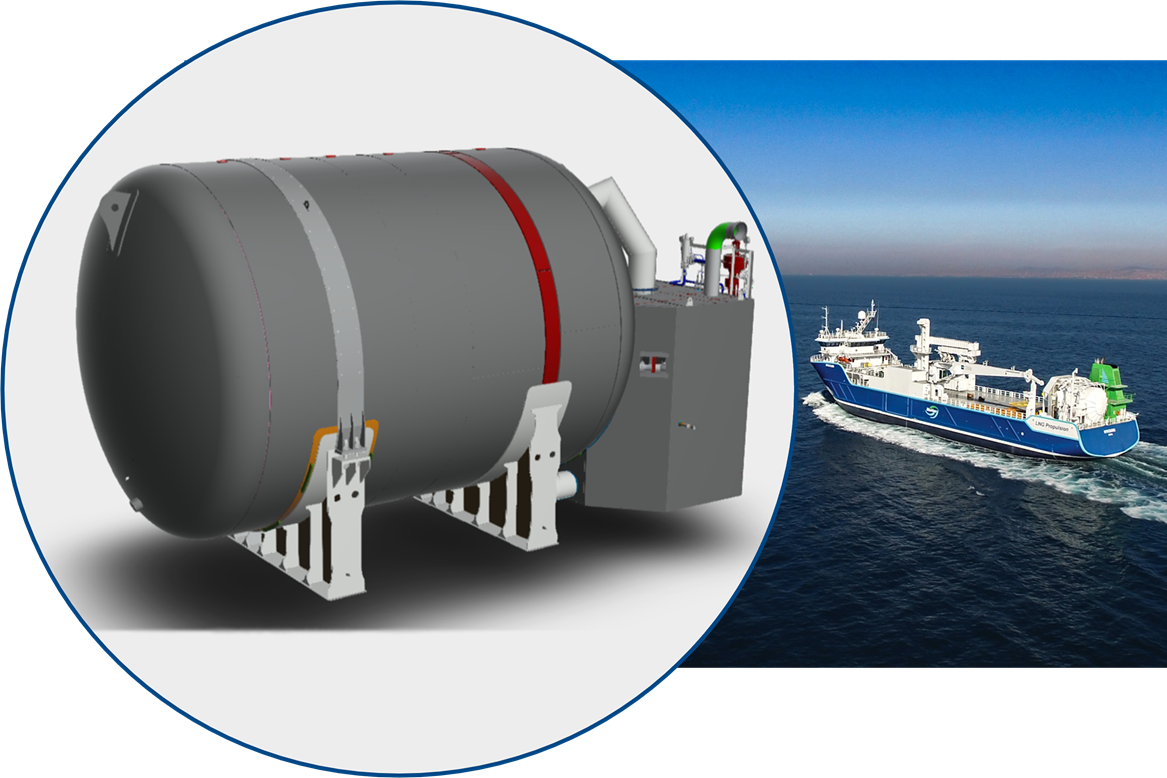

Liquid hydrogen technology requires deep cryogenic expertise. Chart has that pedigree with >800 liquid hydrogen tanks in service around the world across a range of applications including industry, science, research and aerospace.

Fixed Tank System

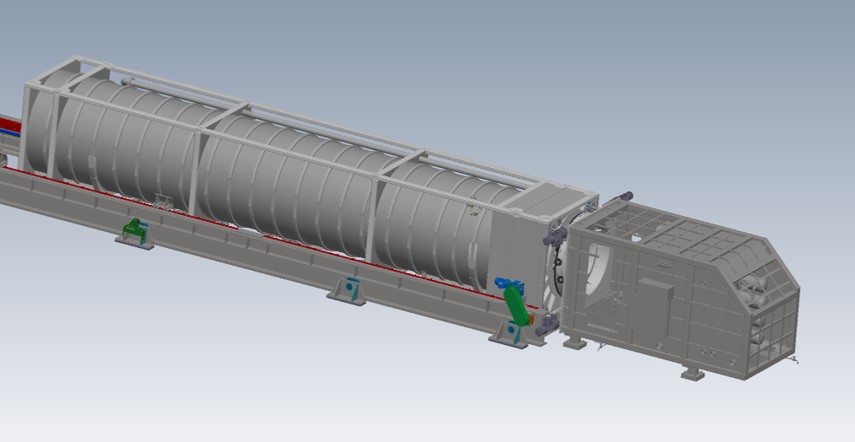

Exchangeable Fuel Tank System

Full for empty exchange solution with simple, fast changeover.

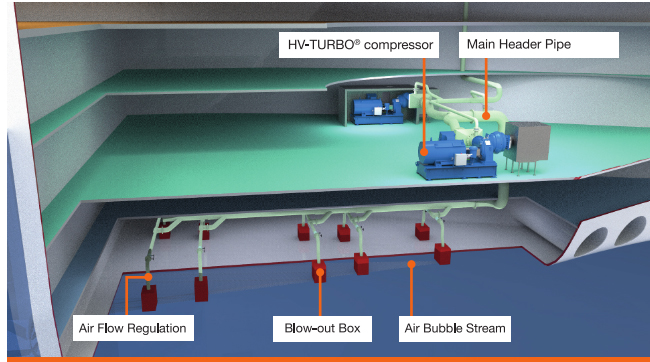

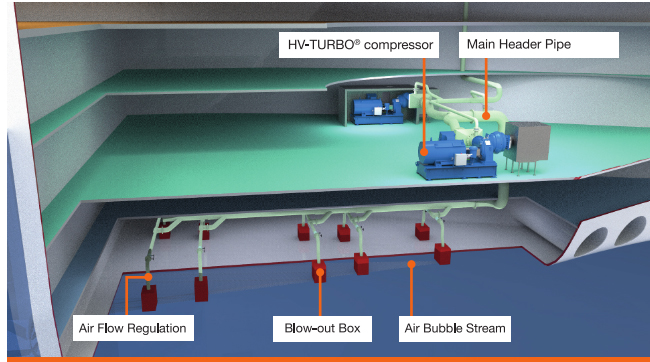

Air lubrication technology is based on blowing micro air bubbles out under the hull of the vessel. The air bubble distribution across the hull’s surface, reduces the resistance generated between the ship’s hull and the water, thus generating an estimated fuel saving of up to 7-10%. Air Lubrication Systems can be used in all types of vessel operations.

ChartMarine has combined in-house compression expertise and proprietary partner air distribution box design technology to create the most efficient air lubrication system with the smallest footprint.

Exhaust Gas Recirculation (EGR) is a method to significantly reduce the formation of Nitrogen Oxides (NOx) in marine diesel engines. By using this technology, vessels are able to meet with the IMO NOx Tier III standard emission limits applying to the North American and United States Caribbean Sea as well as any new Emission Control Areas.

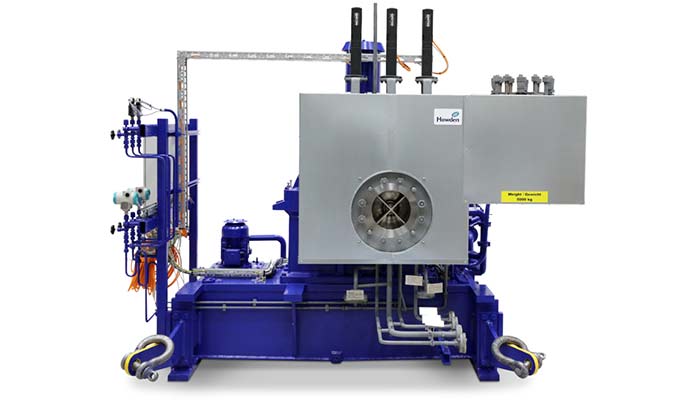

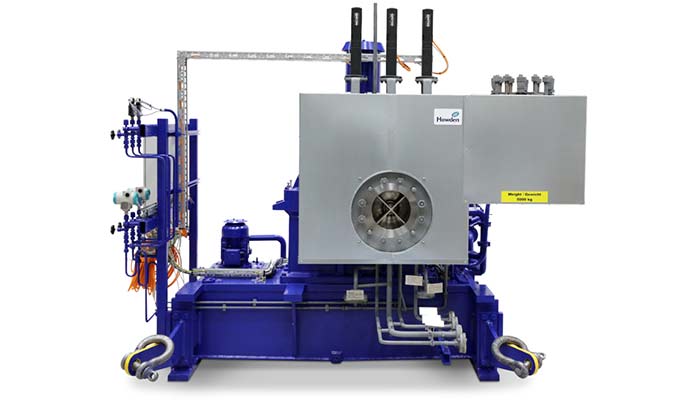

The EGR compressor is a single-stage turbo-compressor with oil lubricated bearings, direct driven with an asynchronous motor and a variable frequency drive. The design features the unique flow optimization mechanism, utilizing inlet guide vanes to optimize efficiency for a given motor rating.

The core compressor features an impeller, milled from a solid, forged piece of duplex stainless steel with an optimal weight/strength ratio. All parts in contact with the medium are made of corrosion resistant steel. The compressor is equipped with a contact free carbon floating ring sealing to ensure that no exhaust gas can escape from the compressor casing.

The EGR turbo-compressor is available in two sizes:

Howden offers a wide range of axial fans to supply and process air within critical and demanding processes across multiple industries.

We have been at the forefront of axial fan technology since the earliest days of its development, and we continue to lead the world in raising energy efficiency, improving reliability and reducing lifetime costs for our customers.

Many of our fans are serving in applications where durability and performance is key to continued operations. Our substantial installed base and long customer relationships bear witness to the high-quality finishing of our fans and excellence in engineering design. This is carried through from bespoke fans for power and mining to standardised fans supporting ventilation in transport tunnels and air provision in light industrial settings.

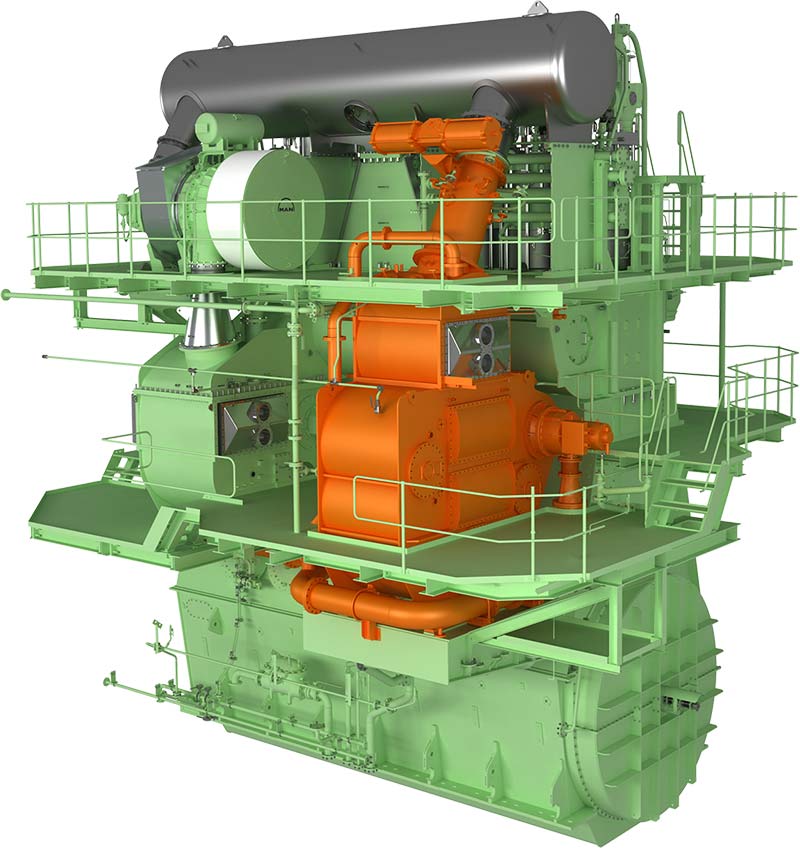

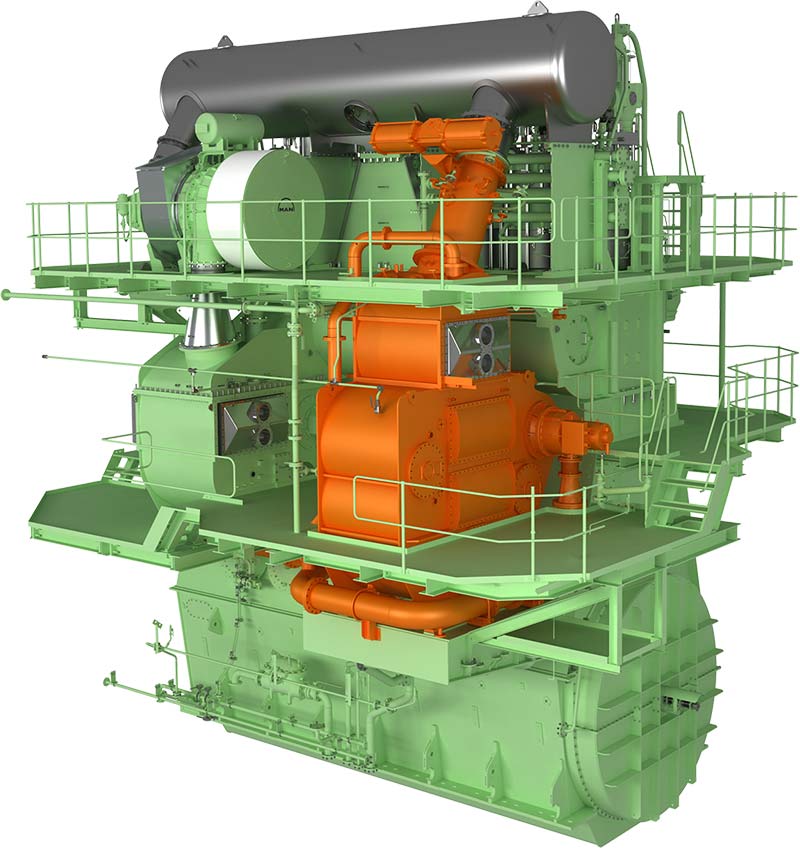

Our steam turbines have a rich history. These 'Dampfturbine' were originally designed and manufactured by Kuhnle, Kopp & Kausch AG - formed in 1899 and have subsequently been manufactured under the name Siemens Turbomachinery Equipment.

A unique feature of these steam turbines is the way that they have been designed to be modular, so that they can be connected in a huge different number of combinations. This makes them incredibly flexible and therefore able to fit with a wide range of customer requirements.

Steam Turbines are designed to turn energy from fluid onto the rotor, and our products are considered the most economical and flexible turbines that you can get. The steam turbines can be used as a generator drive for power generation, or as a mechanical drive for your rotating equipment such as compressors and pumps.

Air lubrication technology is based on blowing micro air bubbles out under the hull of the vessel. The air bubble distribution across the hull’s surface, reduces the resistance generated between the ship’s hull and the water, thus generating an estimated fuel saving of up to 7-10%. Air Lubrication Systems can be used in all types of vessel operations.

ChartMarine has combined in-house compression expertise and proprietary partner air distribution box design technology to create the most efficient air lubrication system with the smallest footprint.

Exhaust Gas Recirculation (EGR) is a method to significantly reduce the formation of Nitrogen Oxides (NOx) in marine diesel engines. By using this technology, vessels are able to meet with the IMO NOx Tier III standard emission limits applying to the North American and United States Caribbean Sea as well as any new Emission Control Areas.

The EGR compressor is a single-stage turbo-compressor with oil lubricated bearings, direct driven with an asynchronous motor and a variable frequency drive. The design features the unique flow optimization mechanism, utilizing inlet guide vanes to optimize efficiency for a given motor rating.

The core compressor features an impeller, milled from a solid, forged piece of duplex stainless steel with an optimal weight/strength ratio. All parts in contact with the medium are made of corrosion resistant steel. The compressor is equipped with a contact free carbon floating ring sealing to ensure that no exhaust gas can escape from the compressor casing.

The EGR turbo-compressor is available in two sizes:

Howden offers a wide range of axial fans to supply and process air within critical and demanding processes across multiple industries.

We have been at the forefront of axial fan technology since the earliest days of its development, and we continue to lead the world in raising energy efficiency, improving reliability and reducing lifetime costs for our customers.

Many of our fans are serving in applications where durability and performance is key to continued operations. Our substantial installed base and long customer relationships bear witness to the high-quality finishing of our fans and excellence in engineering design. This is carried through from bespoke fans for power and mining to standardised fans supporting ventilation in transport tunnels and air provision in light industrial settings.

Our steam turbines have a rich history. These 'Dampfturbine' were originally designed and manufactured by Kuhnle, Kopp & Kausch AG - formed in 1899 and have subsequently been manufactured under the name Siemens Turbomachinery Equipment.

A unique feature of these steam turbines is the way that they have been designed to be modular, so that they can be connected in a huge different number of combinations. This makes them incredibly flexible and therefore able to fit with a wide range of customer requirements.

Steam Turbines are designed to turn energy from fluid onto the rotor, and our products are considered the most economical and flexible turbines that you can get. The steam turbines can be used as a generator drive for power generation, or as a mechanical drive for your rotating equipment such as compressors and pumps.

Onboard fuel gas supply systems comprise all elements for storage and delivery of natural gas to the ships engines:

Chart has provided LNG fueling systems for a variety of marine vessels including ships operating on China's inland waterways and high seas through to the world's fastest and cleanest high speed ferry.

Full service scope including delivery and commissioning according to applicable codes (DNV, LRS, BV, ABS, USCG).

Solutions for coastal, inland water boats and ships.

Systems can be incorporated into newly built and/or converted LNG fueled vessels.

River traffic can be intensive, moving goods and passengers on our main fluvial arteries. The associated emissions are a source of not only high local particulate emissions, but also of atmosphere warming CO2.

Chart’s small scale LNG FGSS and upcoming liquid hydrogen FGSS allow existing vessels, as well as new builds, to be adapted to run safely and cleaner.

Coastal receiving, storage and distribution terminals with jetty fueling module

Chart complete shore to ship bunkering terminals include cryogenic storage tanks, vacuum insulated piping, vaporization and loading arms.

Cryogenic storage tanks are shop built and other components typically supplied as modules, often skid mounted. This reduces construction time at site and allows future capacity expansions to be incorporated into the initial plant design.

Chart cryogenic tanks provide high thermal performance with extended hold times to deliver significantly lower lifecycle costs versus standard tanks.

Chart vacuum insulated pipe decreases heat leakage by 90% and offers a functional life 10x longer than mechanically insulated pipe.

-1167-wide.jpg)

-5-1167x450.jpg)

Chart can always be relied upon for innovation to deliver the optimum solution.

For example, this bunkering terminal in Norway fuels a fleet of feeder vessels serving offshore fish farms. An integral evaporation plant vaporizes LNG to provide natural gas for the boilers at the adjacent fish feed production factory.

Access and download literature, specifications, case studies and more.

Customer Service Americas +1 800 400 4683

Customer Service Europe +420 412 507 234

Customer Service China +86 519 8596 6000