About Fronti

Fronti Fabrications was started by Joe Fronti Jr. in 2003 from his garage. After quickly establishing a reputation in the cryogenic industry for quality workmanship and excellent service, Fronti upsized and were able to undertake much larger projects from new premises, while still upholding their reputation for reliability. The business continued to flourish and a further move was necessary, to Palmerton, PA. Doubling the workspace enabled Fronti to build even bigger assemblies and add a machining department and large rollers.

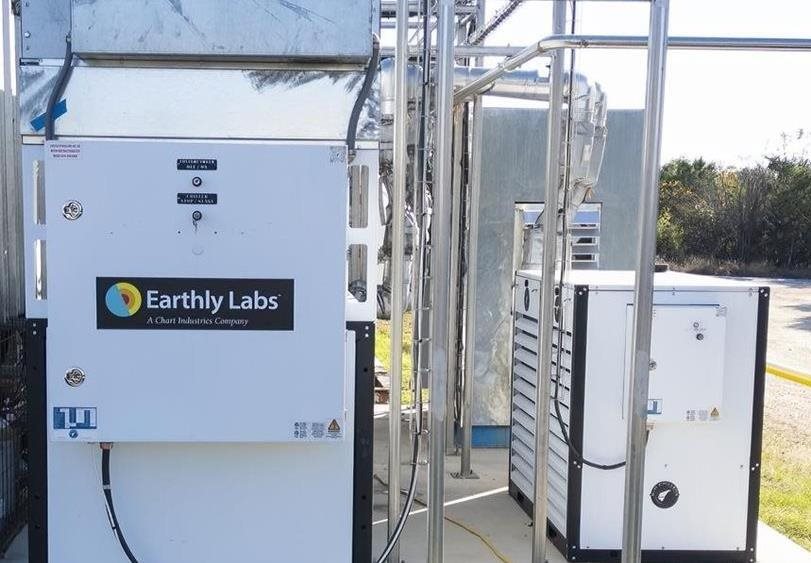

Fronti adds a known team to expand Chart’s cold box manufacturing capacity and capability, including building hydrogen and helium liquefiers. The acquisition increases our under-roof cold box fabrication capabilities by approximately 25% as well as providing additional capacity for battery assembly, perlite cold box fabrication, and specialized vessel and skid fab capabilities. Due to its strategic location Fronti will also provide service and repair staging for our United States industrial gas customers’ installed base.

Featured Products

Video Section

Fabrication

Fabrication is the heart of Fronti's business, with the use of all other resources, building large and small scale projects is truly a specialty. Customers and employees love to see raw materials put through their paces in order to create something extraordinary.

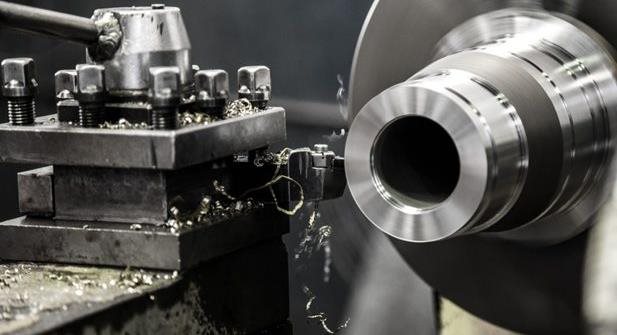

Machining

State of the art ProtoTrak Mill and Lathe allow for conversational programming and manual machining. Conversational programming produces faster prototyping and part design and a Clausing Lathe facilitates industrial material removal and one off parts.

Welding

ASME certified welders with both D1.1 (Carbon Steel) and D1.6 (Stainless Steel) are always on site. Orbital welding capabilities ranging from ½” to 2” Diameter. Welding capabilities ranging from TIG, MIG, flux core, and stick welding with access to Certified Welding inspectors (CWI) at all times.

Quality Control

Quality control meets the standards of the American Society of Mechanical Engineers (ASME). A Certified Welding Inspector (CWI) is always on site to monitor the quality of work. Nondestructive testing is done to ensure quality and consistency throughout all procedures such as helium leak detection and use of dye penetrant.

Contact Fronti

Call Fronti or click the contact us button to send a message.Telephone +1 610 900 6160

-683x475.jpg?ext=.jpg)

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team