LNG Equipment

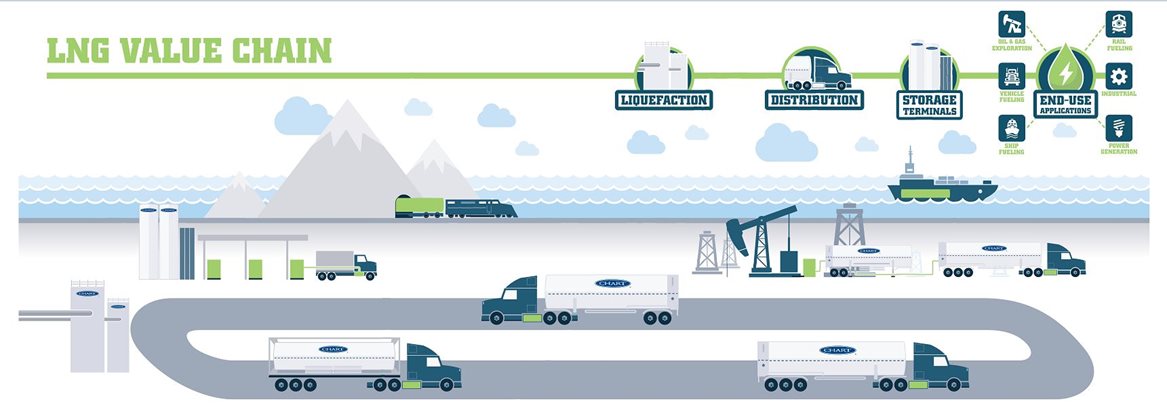

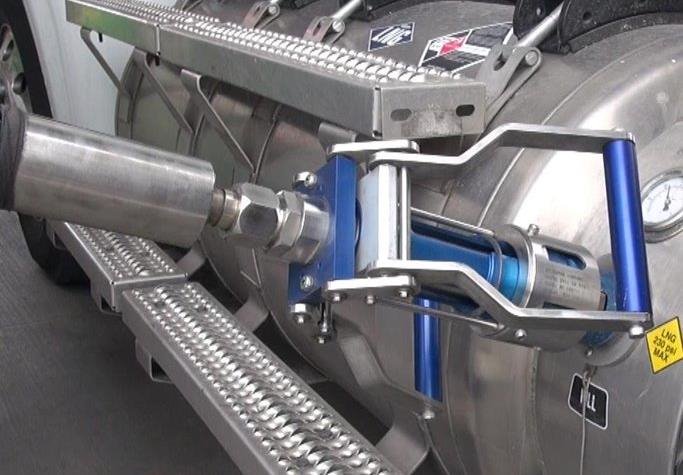

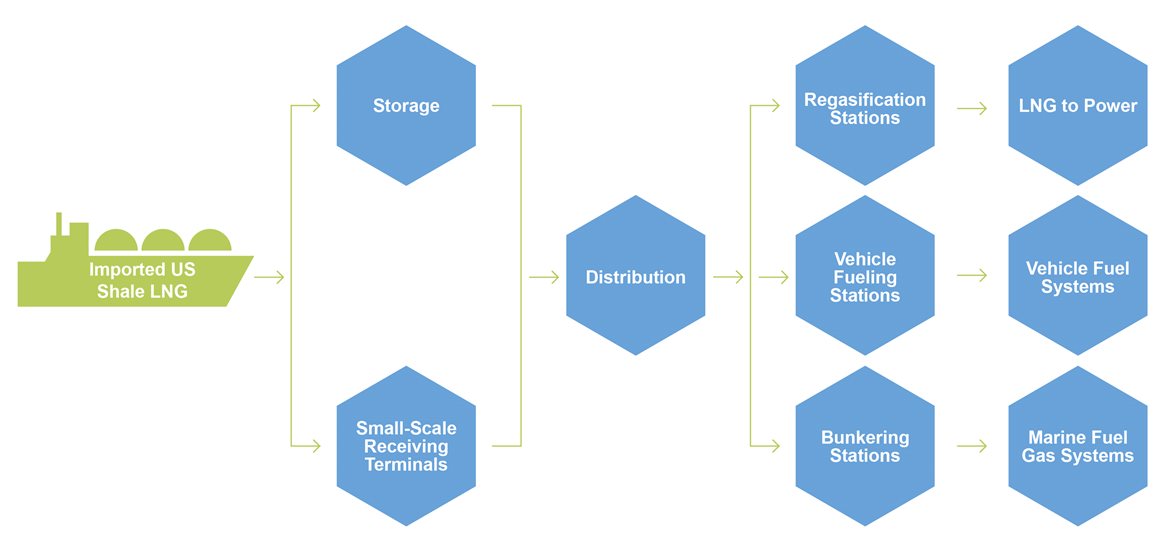

Through the integration of our proprietary core products and technologies we offer ‘Concept to Reality’ solutions facilitating the adoption of liquefied natural gas (LNG) as a safe, economical, clean-burning fuel alternative for energy, transportation and in industry.

.jpg?ext=.jpg)

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team