Turboexpanders

2023 marks L.A. Turbine's (LAT) 20th anniversary designing, building and servicing LAT & non-OEM turboexpanders for hydrocarbon processing, petrochemicals, industrial gas and power generation & recovery applications.

Founded in 2003 as an aftermarket turboexpander services provider, LAT has evolved into a leading OEM specialist providing application-specific turboexpander equipment for multiple applications. Our FX-TURBO Team provides extensive global aftermarket support and field service.

Increase productivity and revenue with a turboexpander built to generate power, process hydrocarbons and recover liquids.

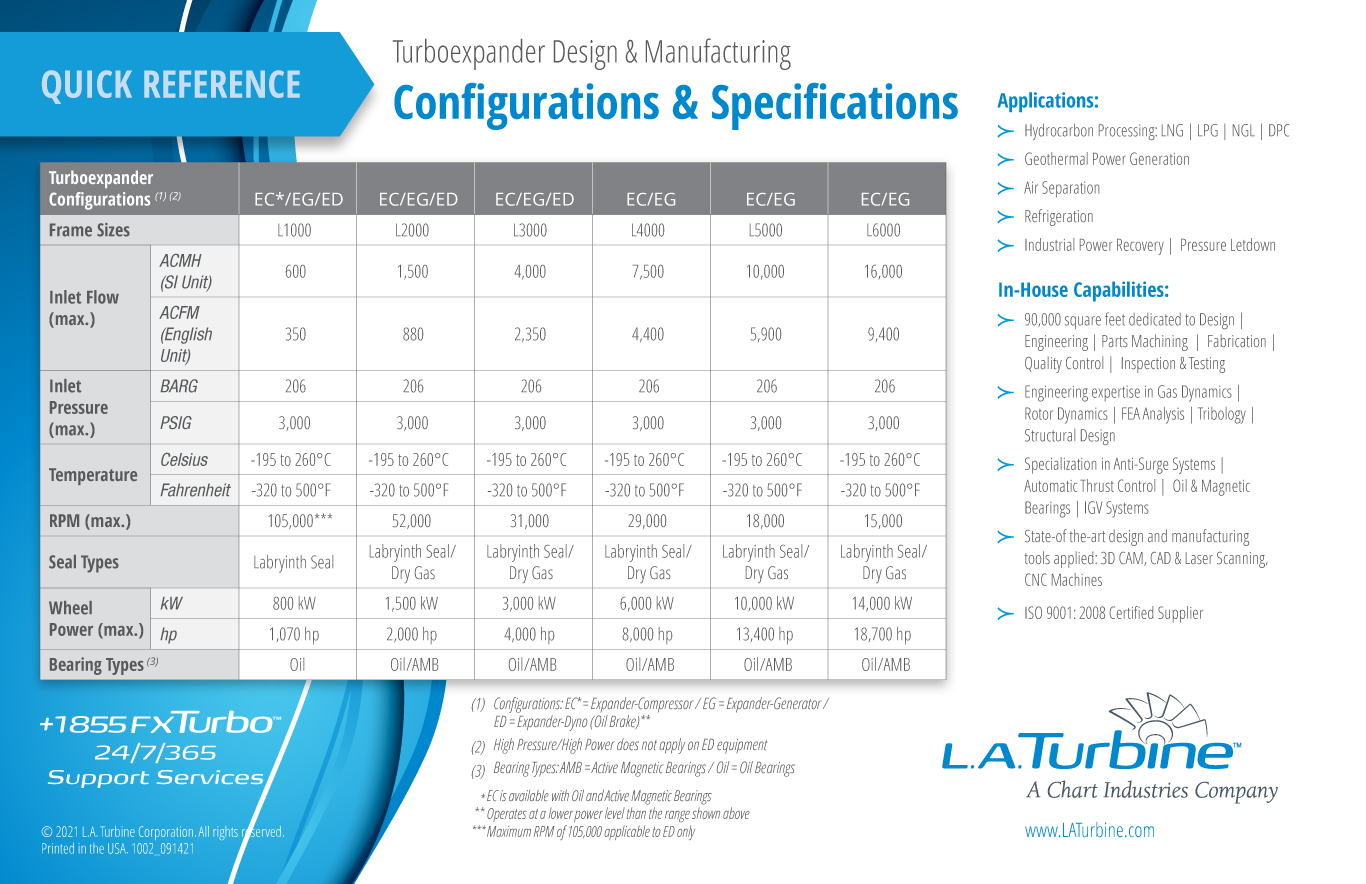

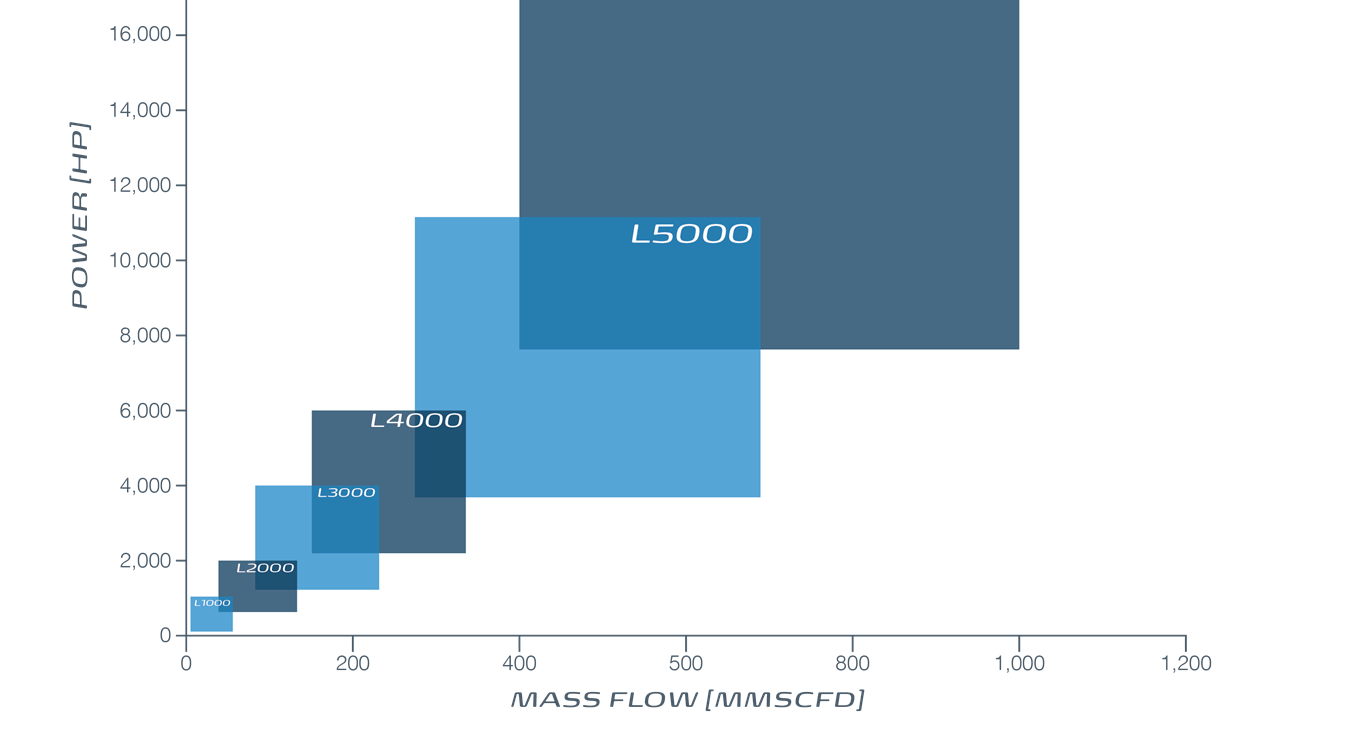

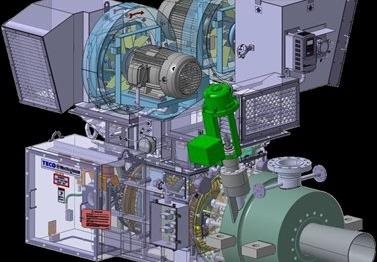

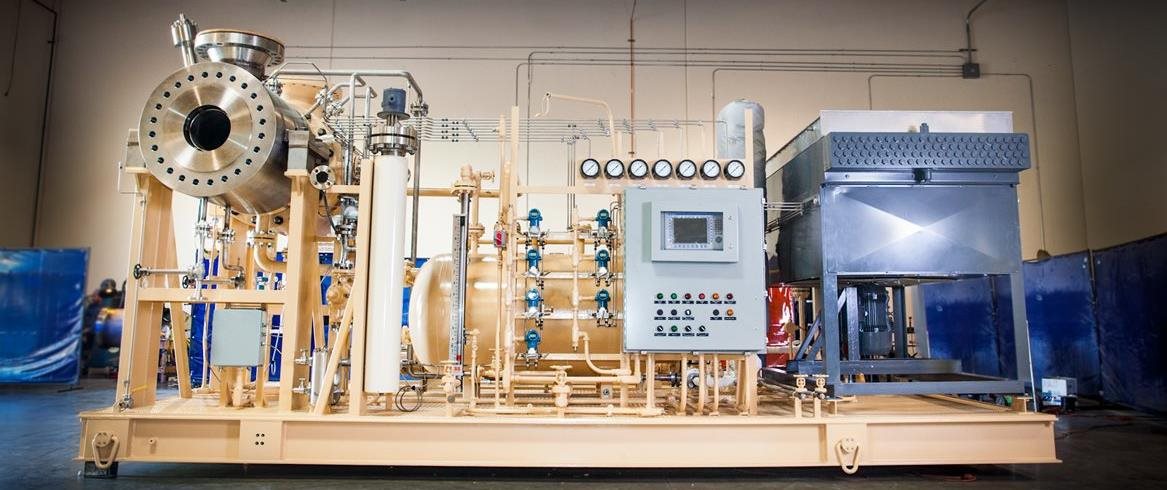

L.A. Turbine turboexpander configurations include expander-compressors with either oil or active magnetic bearings (AMB), expander dynamometer (oil-brake) equipment and specialized turboexpander designs using an expander-generator or high-speed direct-drive expander generators.

Within high-speed turboexpander-compressors, high-pressure gas expands across the turbine, the energy potential in the gas is extracted and transferred through the shaft and to the compressor. The resultant pressure reduction combined with efficient energy extraction produces the refrigeration necessary for cryogenic gas.

Turboexpander-dynamometers, also referred to as an expander-dyno/oil brake, are high-speed machines composed of an expander stage loaded by an oil brake instead of a compressor or generator. The power generated by the expander is dissipated as heat in the oil brake, supported by a lube oil system that provides cooling and bearing lubrication.

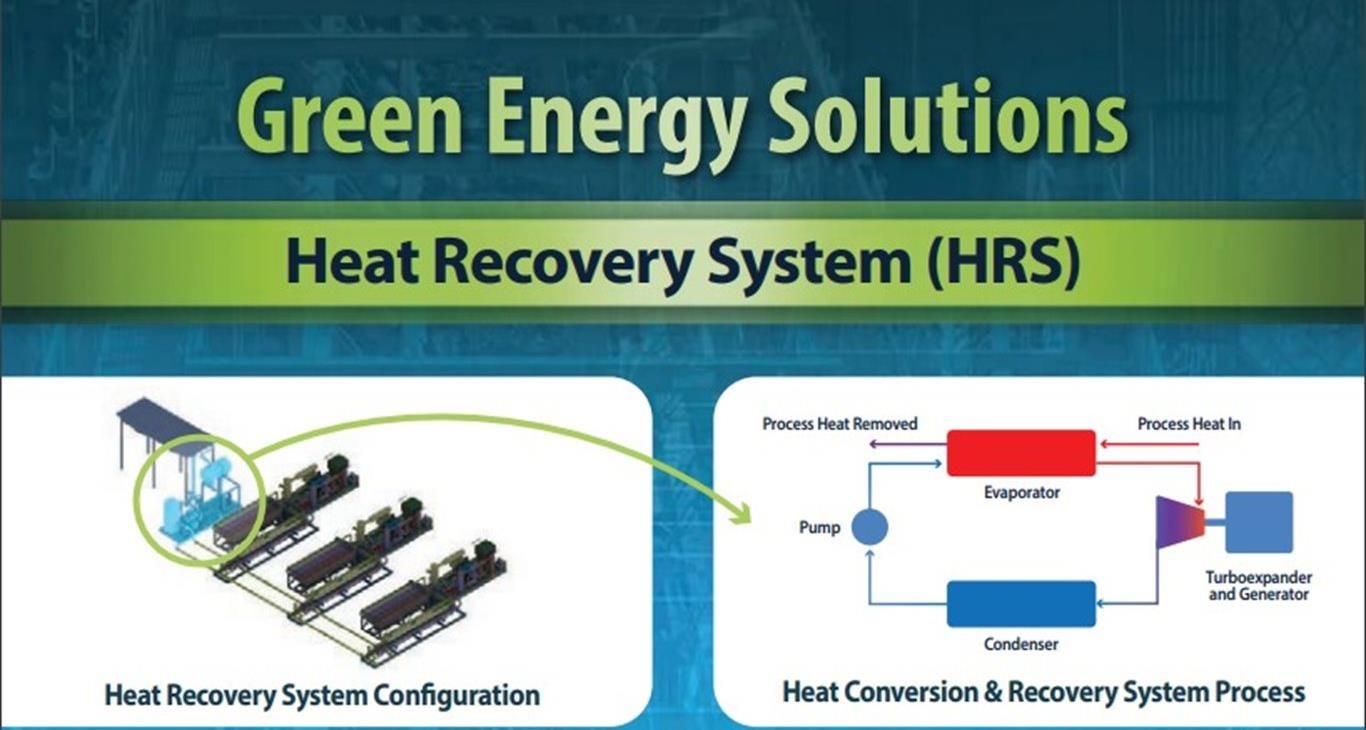

L.A. Turbine offers specialized turboexpander configurations such as expander-generator and high speed direct-drive expander-generator designs used for energy recovery, power generation, and recently, a heat recovery application.

LAT turboexpanders play an important role in providing hydrogen and helium liquefaction solutions for Chart Industries' Nexus of Clean™ offerings for the clean energy transition.

LAT turboexpanders are also used in hydrocarbon processing (Dew Point Control | Ethylene | Propylene | LPG | LNG | NGL Recovery |PDH), industrial gas separation and liquefaction (Air Separation |Helium | Hydrogen| Nitrogen Liquefaction) and power recovery and generation (Geothermal | Organic Rankine Cycle | Waste Heat Recovery).

LAT designs and builds turboexpanders for hydrocarbon processing, industrial gas liquefaction and power recovery and generation.

Turboexpander designs include expander-compressors with active magnetic bearings (AMB) or oil bearings, expander-dynos (oil brake), expander-generators, high-speed direct-drive expander generators and specialized machines.

Turboexpanders are highly engineered machines operating under extreme pressure, temperature and speed. To ensure each turboexpander meets the performance, flow and quality requirements, L.A. Turbine uses multiple engineering approaches in the design process. All engineering design and development processes are ISO 9001:2008 compliant.

Read how LAT became a trusted aftermarket services & OEM turboexpander provider to owner/operators & EPCs.

Access and download literature, specifications, case studies and more.

Global Consult & Service (24/7) +1 855 FX-TURBO or +1 855 398 8726

Sales & Engineering Office +1 661 294 8290