Mechanical Vapor Recompression

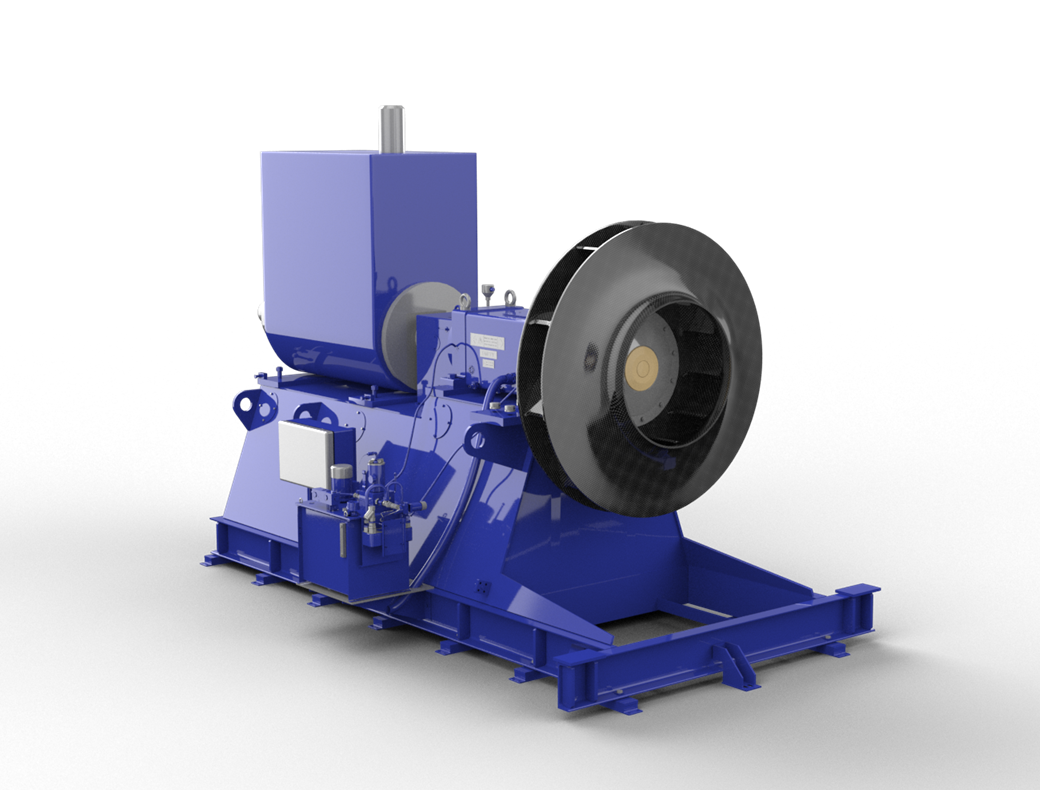

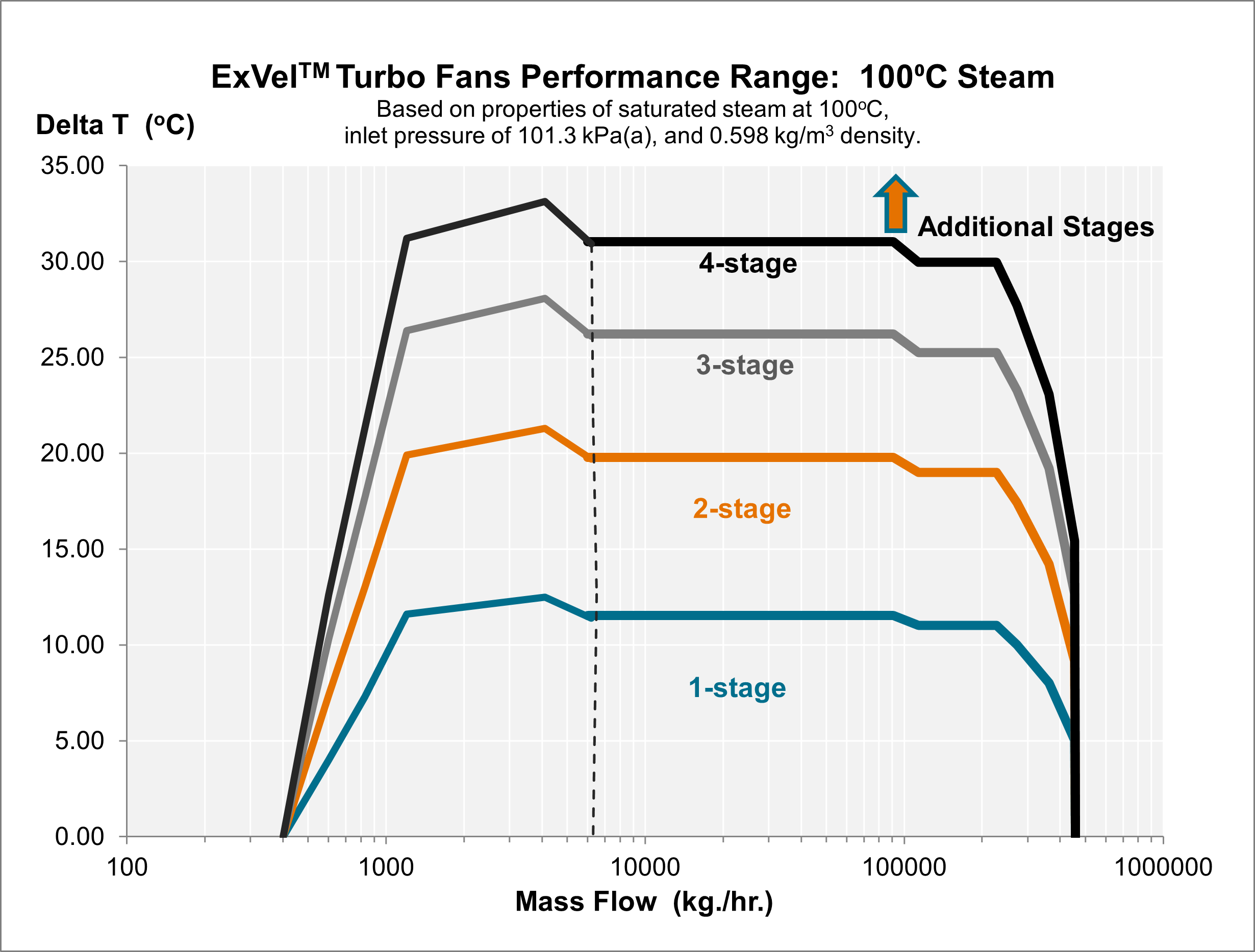

Howden understands the unique process, aerodynamic, mechanical, and operational challenges requirements of Mechanical Vapor Recompression (MVR) applications, which differ from almost all other applications for rotating machinery industry.

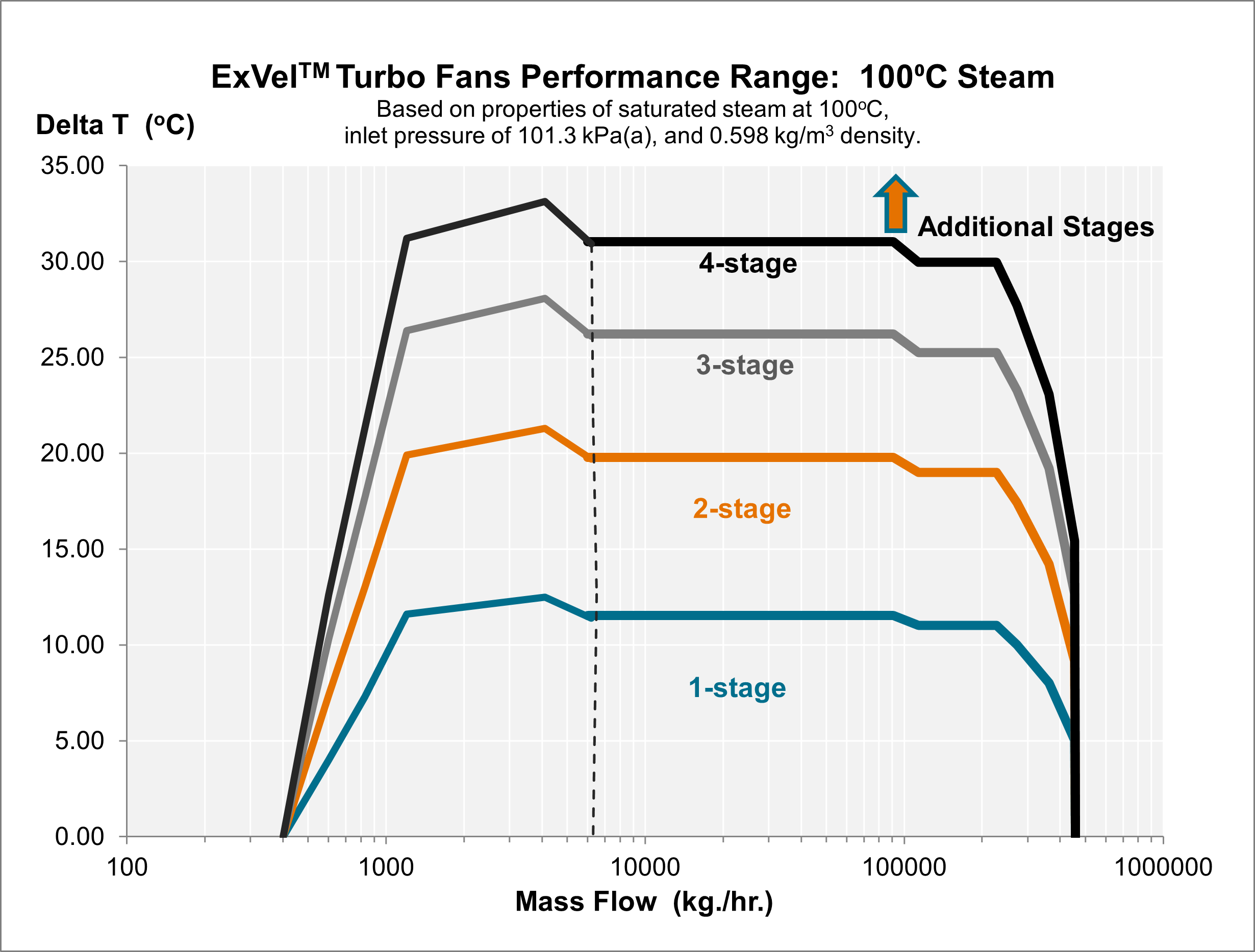

The ExVel™ turbo fan is relied upon across thousands of installations in more than 70 countries to provide the optimum MVR vapor compressor solution. With our extensive MVR application experience over 45 years, we have the know-how to provide the best solution for your plant with our industry leading technologies.

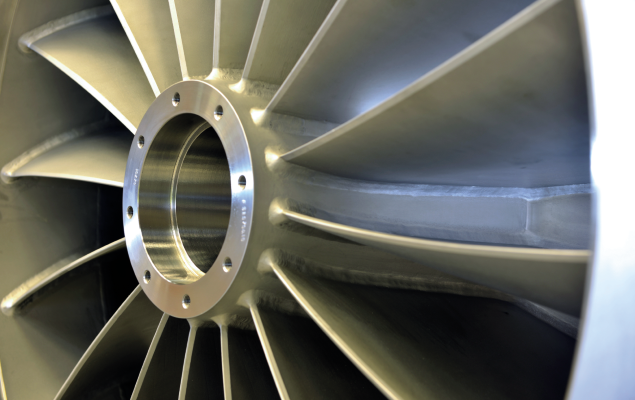

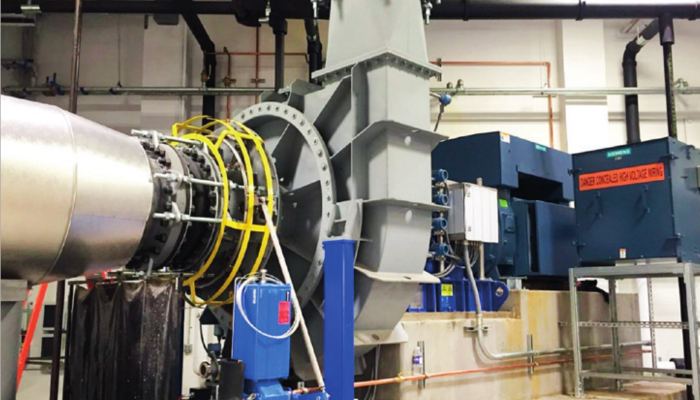

Our unique ExVel turbo fan impeller technologies are unsurpassed in fan industry in terms of strength, rigidity, and load capability. Our fan rotor system is designed and constructed for the application with impeller, shaft, and bearing technologies to stand up to the demanding conditions imparted by tough MVR applications due to process and temperature or chemistry challenges.

While MVR process systems are initially specified by the user to operate in clean steady state conditions, unforeseen process foaming or carryover may occur due to process or operational changes, which can lead to difficult operating condition and environments for the vapor compressor. To provide the highest degree of reliability, users have relied on Howden’s unique ExVel turbo fans to keep their operation online.

Find out more about Howden’s MVR technologies

Request A Quote

Request A Quote

Email An Inquiry

Email An Inquiry

Find Our Locations

Find Our Locations

Join Our Team

Join Our Team