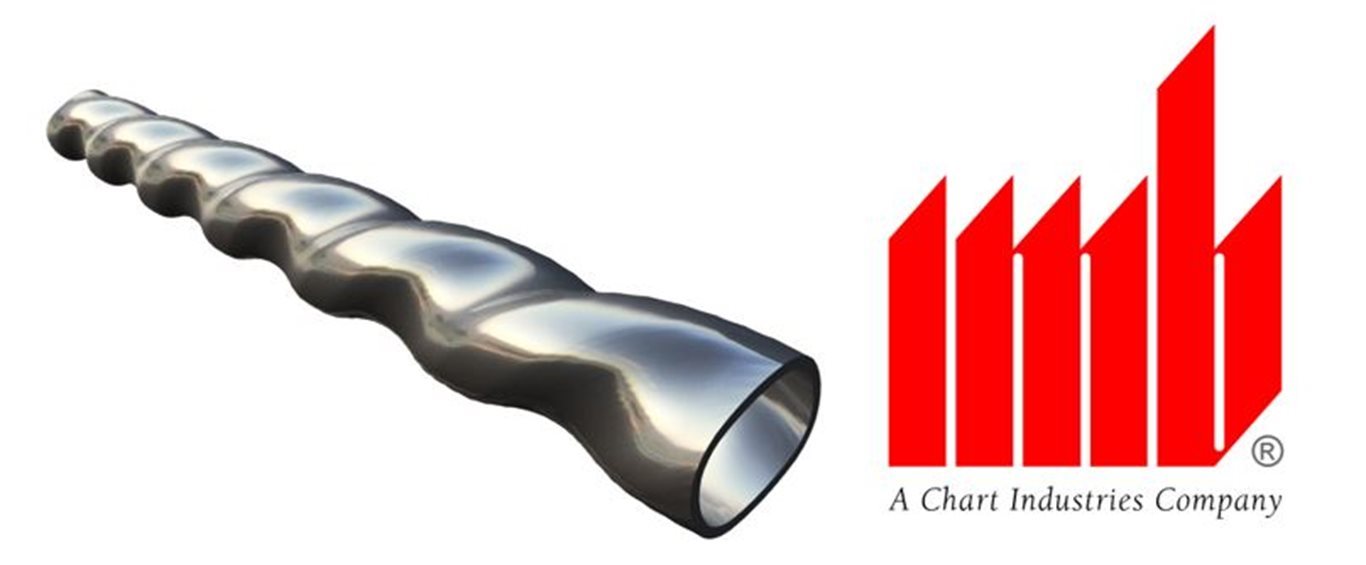

SPINTUBE™ Replacement Bundles

Enhance the performance of TEMA type shell and tube heat exchangers by retro-fitting SPINTUBE™ replacement bundles. SPINTUBE provides increased thermal performance and reduced pressure drop.

Whether it's a new installation or debottlenecking project, the construction of SPINTUBE bundles increases throughput by up to 40% versus conventional shell and tube exchangers while still allowing the same methods for inspection and cleaning. SPINTUBE also completely eliminates flow induced vibrations.

A SPINTUBE replacement bundle creates additional turbulence and with tubes in direct contact with one another the number of tubes per shell diameter is increased. As a consequence retro-fitting SPINTUBE increases thermal performance in the same shell by up to 40%.

No limitations on tube material and thickness. Tube diameters from 3/8" to 11/4". Tube spin is engineered according to service. Can be cleaned using conventional water-jet methods.

Crude pre-heat trains, cooler trains (amine service), condensers, reboilers and vaporizers, feed-effluent exchangers including horizontal, high pressure units e.g. hydrocrackers, and vertical exchangers e.g. Texas Towers, compressor gas coolers.

Thermal performance improvements up to 40%, improved hydraulic performance (reduced shell-side pressure drop), custom design, minimized project scope, improved efficiency and throughput, vibration problems eliminated, easy cleaning.

Download and view literature.

IMB +39 0373 237611